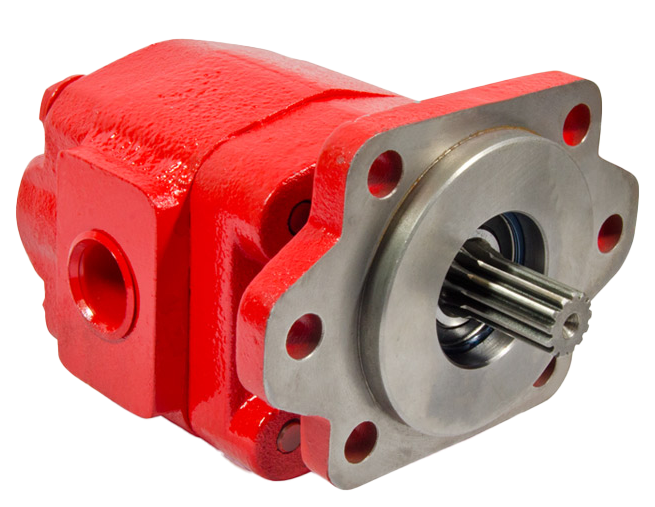

When it comes to hydraulic systems, gear pumps are the go-to choice for many. Their simplicity, durability, and cost-effectiveness make them the most common design in use. Let's delve into the world of gear pumps, exploring their key features, advantages, and applications.

Reliable and Easy to Maintain

Gear pumps are known for their straightforward design, consisting of fewer moving parts compared to other pump types. This simplicity translates into easy servicing and maintenance, reducing downtime and keeping operations running smoothly. Additionally, gear pumps are more tolerant of contamination, ensuring reliable performance even in harsh environments.

Fixed Displacement for Consistent Flow

A notable characteristic of gear pumps is their fixed displacement, also referred to as positive displacement. This means that with each rotation of the pump's shaft, the same volume of flow is produced. This consistency is vital for maintaining optimal performance in hydraulic systems.

Understanding Gear Pump Specifications

Gear pumps are rated based on their maximum pressure rating, cubic inch displacement, and maximum input speed limitation. These specifications provide valuable information for selecting the right pump for a given application. The maximum pressure rating determines the pump's capability to withstand system pressures, while the cubic inch displacement indicates the volume of oil delivered per revolution. Considering the maximum input speed limitation ensures the pump operates within its designed limits.

Applications in Open Center Hydraulic Systems

Gear pumps find widespread use in open center hydraulic systems. In these systems, the pump traps oil between the teeth of its gears and the pump body. It then transports the oil around the gear cavity's circumference before forcing it through the outlet port as the gears mesh. This reliable oil transport mechanism contributes to the consistent operation of hydraulic systems.

Enhancing Efficiency with Thrust Plates

Gear pumps incorporate brass alloy thrust plates, also known as wear plates, to improve pump efficiency. These plates are positioned behind the gear ends and are subjected to a small amount of pressurized oil. This pressure pushes the plates tightly against the gear ends, reducing internal leakage and ensuring efficient oil flow.

Gear pumps play a crucial role in hydraulic systems, offering reliability, ease of maintenance, and cost-effectiveness. Their fixed displacement design and ability to handle contamination make them the preferred choice for many applications. Whether it's in construction, agriculture, or material handling, gear pumps continue to prove themselves as versatile workhorses, providing consistent flow and reliable operation.

Need a gear pump or any other hydraulic pump or component? Click below to get a quote today!