Testing is a crucial step in ensuring the overall performance and reliability of a remanufactured transmission. When purchasing a remanufactured component, you should be able to purchase with confidence. Because if you're buying a rebuilt part that wasn't tested in the facility, the rebuilders are using your machine as a test bench.

How does the testing process work?

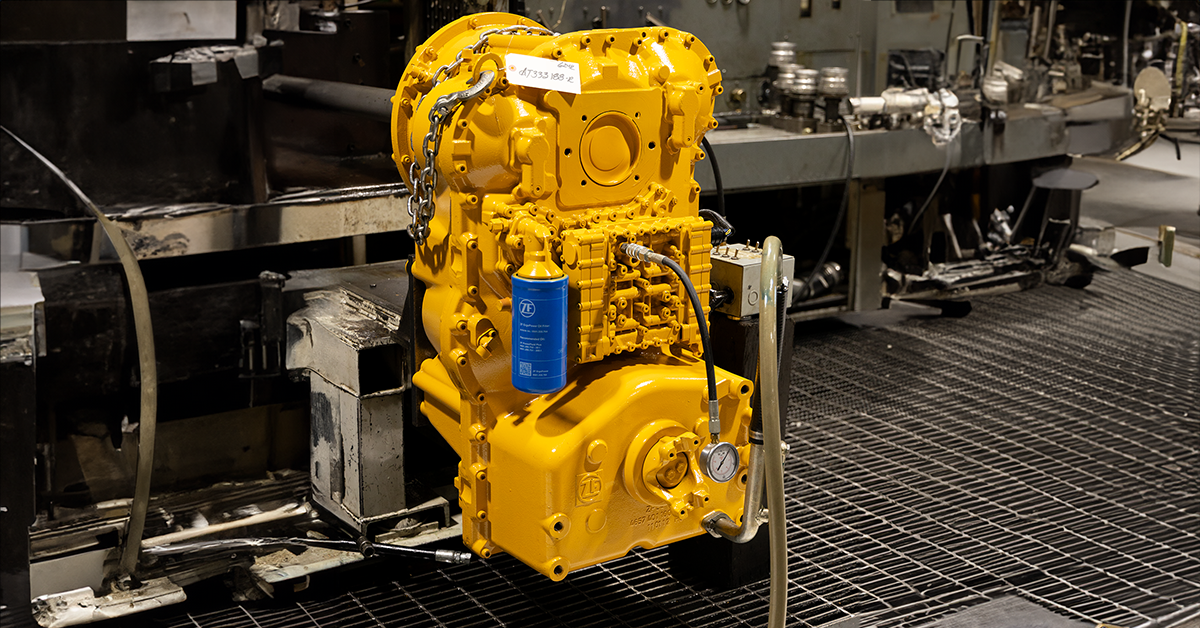

We visited ome of the very best in the business when it comes to remanufactured components, OEM Replacement Parts, located in Texas. Specializing in remanufacturing axles and transmissions, they had a comprehensive outline for us on how much goes into testing and retesting their parts before it ever leaves their doors.

Step 1: Transmission Identification and Preparation

Before diving into the testing process, it's essential to identify the specific transmission model you are working with. This guide was written about a John Deere 624K Loader transmission.

Tips on indentifying the transmission you have:

- Check your operator's manual for your machine.

- Find the identification plate located on the transmission, which usually includes: model number, serial number, and group number. Do a quick search online, and you should be able to find your transmission!

- (Best way) Find the serial number located on the transmission, give ConEquip Parts a call, and we will help you find a high quality replacement transmission for your machine.

Step 2: Hydraulic Pump Setup

The heart of the testing process lies in the hydraulic pump setup. This setup mimics the function of the engine, driving the transmission's driveshaft. The goal is to simulate real-world conditions to assess the transmission's performance accurately.

Step 3: Initial Checks

They conduct initial checks by verifying torque converter flow to the cooler and assessing torque converter pressure. These checks provide insights into the transmission's fluid dynamics and pressure regulation. After that, they get confirmation that the system has correct pressure. This is a critical parameter that influences the transmission's overall functionality. Remember, they are testing for real world application, and if it's going to break, they want it to break there, not after being installed on your machine.

Step 5: Clutch Pack Testing

They use a hydraulic pump to drive the drive shaft, simulating what the engine would be doing on the machine. This is because they are able to hear any abnormalities in the operation of the transmission better than if they were constantly running a diesel engine next to the test bench.

After the hydraulic oil has started cycling through, they check the pressue of the torque converter, as well as the system pressue one more time. To do this, they run the transmission at approximately half the idle RPM to ensure proper oil flow before proceeding. Then they can start energizing the clutch packs one by one, as the ECM would, checking each gear individually.

Step 6: Sequential Gear Testing

Incrementally increasing the RPM, the mechanic progresses through each gear in the transmission, dropping RPM to transition to the next gear. This allows each gear to be assessed individually to make sure varying loads won't cause the transmission to quit. While going through each gear, including reverse, they check for odd noises, leaks, or abnormalities.

Step 7: Document and Ship

Once the transmission has passed all the tests, they document everything, and get it ready to ship out to the customer.

We want to personally thank the great guys over at OEM Replacement Parts for allowing us to witness and document the in-depth process of testing that every remanufactured transmission goes through before leaving their facility. Need a transmission or an axle? Give us a call and we can hook you up, for any make or model!