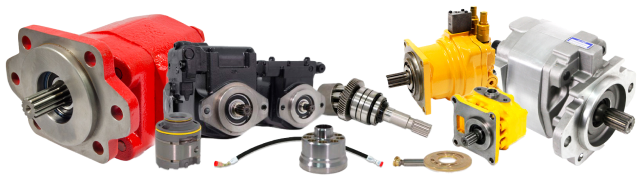

Exploring Hydraulic Pump Types for Mobile Applications

When it comes to hydraulic systems in mobile applications, there are three main types of hydraulic pumps: gear pumps, piston pumps, and vane pumps. Each type has its unique features and applications. Click each header to learn more!

Gear Pumps

Gear pumps are the most commonly used design in heavy equipment hydraulic systems. They offer several advantages:

- Simple design with fewer moving parts

- Easy to service and maintain

- Tolerant of contamination

- Cost-effective option

Gear pumps are fixed displacement pumps, meaning they deliver a consistent volume of flow with each rotation of the pump's shaft. They are rated based on maximum pressure, cubic inch displacement, and maximum input speed. Gear pumps are typically used in open center hydraulic systems, where oil is trapped between the gears and transported around the gear cavity before being forced through the outlet port.

Piston Pumps

When high operating pressures are required, piston pumps are the go-to choice. They offer the following features:

- Withstand higher pressures compared to gear pumps

- Suitable for applications with variable system flow requirements

Piston pumps have a more complex design and require a deeper understanding for proper operation and maintenance. They consist of a cylinder block containing pistons that draw oil from the supply port and force it through the outlet. The piston's stroke length is determined by the angle of the swash plate, which remains stationary while the cylinder block rotates. Piston pumps come in both fixed and variable displacement designs, offering flexibility based on specific application needs.

Vane Pumps

Vane pumps, although less common, have been widely used in heavy equipment in the past. Here's an overview:

- Typically found in older equipment

- Less commonly used today due to the popularity of gear pumps

In a vane pump, oil is picked up between vanes on a rotating cartridge and transported to the pump's outlet. As the area between the vanes decreases on the outlet side and increases on the inlet side, oil is drawn in through the supply port and expelled through the outlet. While vane pumps work similarly to gear pumps, they have a rotating cartridge with a single set of vanes instead of gears.

Need a hydraulic pump or any other hydraulic component for your heavy equipment? Click below to get a quote today!