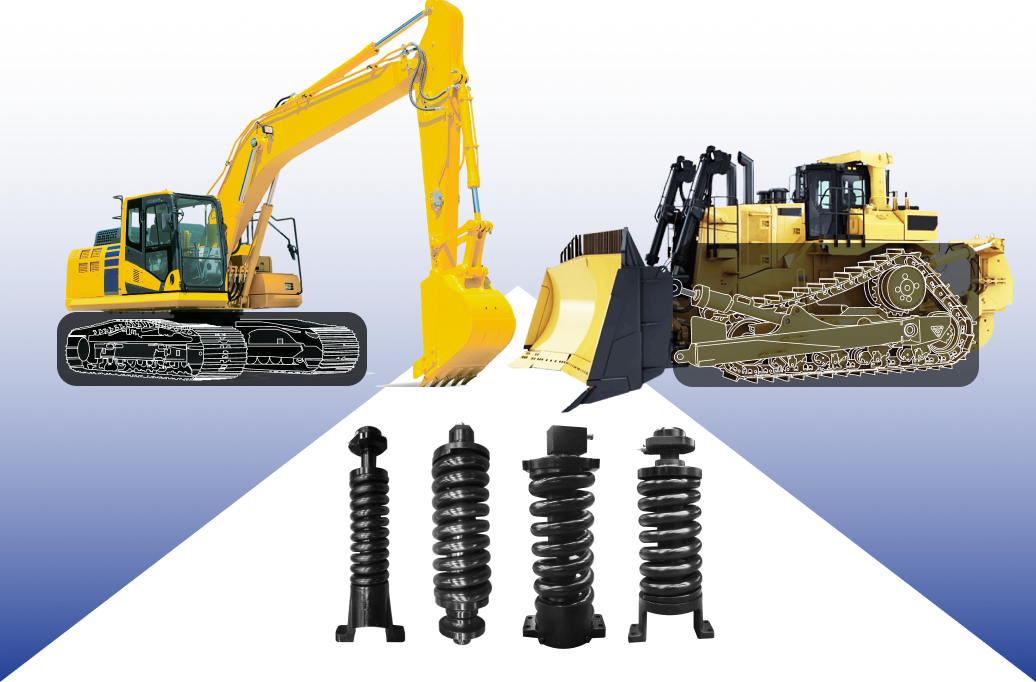

In the world of heavy machinery, proper maintenance is paramount to ensuring smooth operations and minimizing costly repairs. One crucial aspect of this maintenance is track adjusters, a component often overlooked but vital for the efficiency and longevity of equipment.

What Do They Do?

Track adjusters play a pivotal role in heavy equipment functionality. They are responsible for:

-

Pushing the Idler Wheel Forward: This adjustment helps regulate track tension, which is essential for optimal performance.

-

Reducing Slack and Droop: By adjusting the track tension, track adjusters eliminate slack and droop in the tracks, ensuring they remain aligned and efficient.

-

Protecting the Undercarriage: In the face of obstacles such as tree stumps, rough terrain, or holes, track adjusters safeguard the undercarriage from potential damage.

What Can You Control?

Two main factors fall under your control when it comes to track adjusters:

-

Track Tension: Proper track tension is critical for the machine's stability and performance. Too loose tracks can lead to detracking or derailing, while overly tight tracks result in increased wear and tear on various components.

-

Operator Skill: The operator's proficiency in assessing track conditions and adjusting tension when needed significantly impacts equipment longevity.

Understanding Track Tension

Track tension is a balance that shouldn't be overlooked. The repercussions of improper tension can be severe:

-

Loose Tracks: Detracking or derailing can occur due to insufficient tension.

-

Excessive Tightness: Overly tight tracks lead to higher stress on components like internal joints, links, track bushings, idlers, rollers, and sprockets.

A general rule of thumb is to maintain around 2 inches of chain droop. This can be measured from the top of the lowest track pad to a straight edge placed across the top of the track pads from the front idler to the top idler. Keep in mind that as operating conditions change, so should your track tension adjustments.

Signs of Failing Track Adjusters

Detecting failing track adjusters is crucial for timely intervention. Signs include:

-

Cracked or Broken Components: Visible damage on the adjuster components indicates potential problems.

-

Excessive Droop in Tracks: If the chain droop exceeds the recommended 2 inches, it's time for an inspection.

-

Hydraulic Fluid Leakage: Common failures include leaking seals, seized pistons, bent shafts, and broken springs.

The Importance of Quick Repair

When a track adjuster fails, swift action is necessary. Ignoring the issue can lead to:

- Premature Wear or Breakage

- Higher Risk of Track Derailment

- Unplanned Maintenance Costs

The role of track adjusters in heavy equipment operation cannot be overstated. Regular maintenance and prompt repairs are key to ensuring their functionality. Remember, track tension and adjuster conditions must be evaluated periodically to keep your machinery running smoothly. By mastering track adjusters, you're taking a significant step toward prolonging the life of your heavy equipment and optimizing its performance.

Need a track adjuster for your machine? Click below to get a quote today!