Keeping construction machines running on your worksite is costing a lot more with fuel prices so high. Midsummer, gas prices are 70% higher than from the same time in 2021. One way or another, you're going to get hit, but you machine owners can minimize the pain with some simple gas saving tips.

First, shop around for your fuel. You can get better prices if you search for them. Also, it is well within your right to ask the vendor what their costs are, so you know if you're getting a good price on their service. Negotiating price is part of a free market system so take advantage of that.

Also, you can use apps such as Gas Buddy or Drivvo to help you find the best prices.

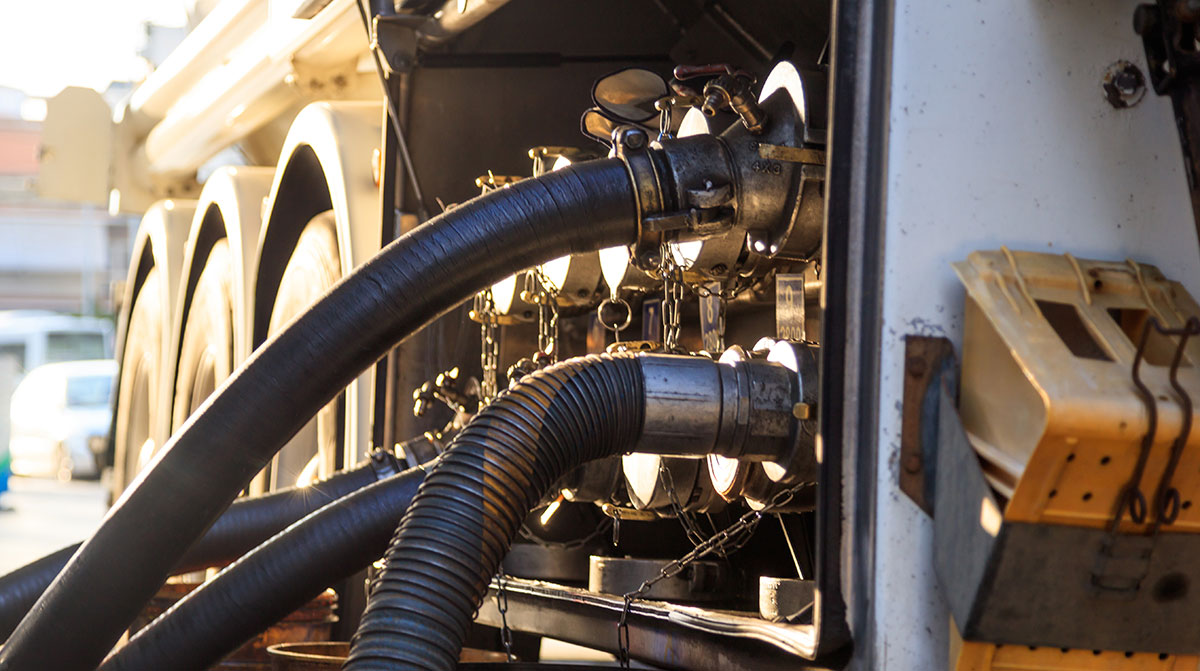

Keep a close eye on your usage so you can make educated decisions about operation, management, and purchasing. A great way to do this is by using fuel management software. Reports from software like FuelMaster will show you what machine is being fueled, how much it is using, miles or hours per gallon, what type of fuel it is burning, and more. This will also help you know if your fuel is being stolen.

Machine maintenance is the most common way to help save on fuel. Be sure your machine is running with clean fuel and air filters. Keep an eye on tire pressure and track tension.

Telematic data offers valuable insight into fuel efficiency and machine utilization as well.

Telematics systems, such as John Deere's JDLink, can track utilization data including idle time, fuel consumed while in idle, and compare that data across the fleet to identify ways to be more efficient.

Fuel burns at different rates depending on what mode or gear your machine is in so keep data on that as well. Telematics will provide all the information you need from workloads to idle time to help your company come up with the best strategies to help save on fuel.

When it comes down to it, you're not going to be able to completely compensate for that aforementioned 70% spike in fuel costs. At best, with fuel saving ideas, you might be able to cut that number down to about 50%. This is where the rising cost of fuel prices must be passed on to your customers. Be completely honest with your clients about the added costs to your service because of rising fuel prices.

One way to do this is to be transparent with a fuel surcharge that is based on a publicly available data source and adjusted monthly.

Across the industry, fuel surcharges have become more common. The result is many contractors are delaying work until fuel prices drop back down to reasonable levels.

Machine owners can also switch to compressed natural gas. CNG runs about half as much as regular fuel. The equipment does need to be converted. Because it is a renewable, clean-burning biofuel, Green Energy, there are a number of government incentives for organizations to convert to CNG.

The one fuel saving idea companies can take, an action many believe government leaders are hoping, and even manipulating companies into taking, is replacing diesel powered machines with battery operated equipment.