Track Pins and Bushings - To Turn or Not to Turn

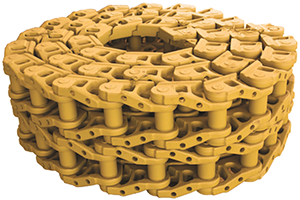

Your bulldozer or excavator chains are getting to a point where it’s time to consider some maintenance. There are a few options including a wet turn, grease turn, pin and bushing replacement, or a complete track swap out.

Making decisions about how best to handle a wearing chain involves a number of factors—including the size of the tractor, its age, condition, application, cost of components, and how you anticipates using the machine going forward.

Knowing how your pins and bushings sustain wear will help you perform certain maintenance tasks to help extend the life of your undercarriage.

Pins and bushings wear internally when there’s a lack of lubrication. The affected area is generally on one side of the pin and on the mating surface of inner diameter of the bushing.

Wear causes the track’s pitch (the distance between pin centers) to extend, resulting in a “stretched” chain that will loosen.

Normal wear on the outside of the bushing also occurs primarily on one side, the reverse-drive side, because the bushing rotates under considerable load at the top of the sprocket when the machine is in reverse. Although the bushing rotates at the same spot during forward travel, the load isn’t as heavy.

Pins need to be flipped while and bushings should be turned 180 degrees as a way to bring new surfaces to working areas, both internally and externally.

Turning restores track pitch and can prolong undercarriage life by enabling the chain to last until links and rollers need attention.

“Turns” on today’s machines with lubricated tracks can be either “wet” or “greased.” During a wet turn, the pins are refilled with oil, a process that involves pulling a vacuum in the pin’s oil reservoir (through a self-sealing plug in the end of the pin) and drawing in new oil.

If the assembly won’t pull a vacuum, chances are that the seals will leak. With a grease turn, pins and bushings are simply reassembled with heavy grease.

Pins and bushings in a SALT chain generally only need turning because of external wear on bushings, since the assembly’s oil supply works to minimize internal wear.

However, many bulldozer and excavator owners soon discover internal wear generally exceeds external wear on a SALT chain.

Have a Question About Undercarriage, Pins or Bushings?

Eventually, SALT chains dry up. Especially low-ground-pressure machines that have wider pads that place more side torque on seals, bushing ends, and link counterbores.

You need to be aware your tracks may not be a good candidate for turning your pins and bushings. There is a point at which there will be so many dry joints that a wet turn isn’t feasible. Sealing surfaces could be compromised, likely to the point the joints won’t hold oil for as long as they need to, even with new seals and thrust washers.

Many bulldozer and excavator owners are forgoing the wet turns because the labor has become expensive and because the internal wear is more than the external wear.

Another option is a grease turn. Most bushings have grooves formed from the old seals and once turned, bushings may not mate properly with new seals. Staying with the old seals and simply greasing the chain over a wet turn can save a significant amount of money.

Sometimes it makes more sense to get another 500 or so hours out of the tracks before replacing all the pins and bushings or you can simply swap out the chains completely and put some brand-spanking new ones on.

The price of aftermarket chains has made that option easier on machine owners as the cost of aftermarket chains can be as much as 50% less than OEM chains without sacrificing much if anything on the quality.