Hydraulic cylinders are a vital component of construction equipment like excavators and bulldozers. These cylinders are responsible for providing the force and motion necessary to operate these heavy machines. However, like any mechanical component, hydraulic cylinders can fail over time, leading to decreased performance and potentially dangerous conditions on job sites. In this article, we'll explore the signs of hydraulic cylinder failure and the reasons why these cylinders can fail.

Signs of Hydraulic Cylinder Failure:

-

Leaking Fluid: One of the most obvious signs of hydraulic cylinder failure is the presence of leaking fluid. This can manifest as visible drips or puddles of hydraulic fluid around the cylinder. In some cases, the fluid may be difficult to see, but you may be able to detect its presence by feeling for dampness or stickiness around the cylinder.

-

Reduced Performance: As a hydraulic cylinder begins to fail, you may notice a reduction in its overall performance. This can include slower movement or decreased force output. You may also notice that the cylinder is no longer able to maintain its position when under load.

-

Strange Noises: If you hear any unusual noises coming from the hydraulic cylinder, such as squeaks or grinding sounds, this could be an indication of impending failure. These noises may be caused by worn or damaged components within the cylinder.

-

Visual Damage: If you notice any visible damage to the cylinder, such as dents or cracks, this could be a sign of impending failure. Damage to the cylinder can compromise its structural integrity and lead to catastrophic failure.

-

Overheating: Hydraulic cylinders can overheat if they are not functioning properly. If you notice that the cylinder is hot to the touch or that the hydraulic fluid is overheating, this could be a sign of impending failure.

Reasons Why Hydraulic Cylinders Fail:

-

Wear and Tear: Like any mechanical component, hydraulic cylinders experience wear and tear over time. This can cause seals and other components to degrade, leading to leaks and reduced performance.

-

Contamination: Hydraulic fluid can become contaminated with dirt, debris, and other particles over time. This contamination can cause damage to the cylinder's internal components and lead to failure.

-

Overloading: If a hydraulic cylinder is subjected to loads that exceed its rated capacity, this can cause damage to the cylinder and lead to failure.

-

Corrosion: Hydraulic cylinders can corrode over time, particularly if they are exposed to corrosive environments such as saltwater or acidic conditions.

-

Improper Maintenance: If hydraulic cylinders are not properly maintained, they can fail prematurely. This can include failure to change the hydraulic fluid, neglecting to replace worn components, or failing to lubricate moving parts.

Hydraulic cylinder failure can have serious consequences on construction equipment like excavators and bulldozers. By being aware of the signs of impending failure and understanding the reasons why hydraulic cylinders fail, operators can take steps to prevent catastrophic failures and ensure safe and efficient operation of their equipment. Regular maintenance and inspections can help identify potential issues before they become major problems, ensuring that hydraulic cylinders continue to function properly and reliably for years to come.

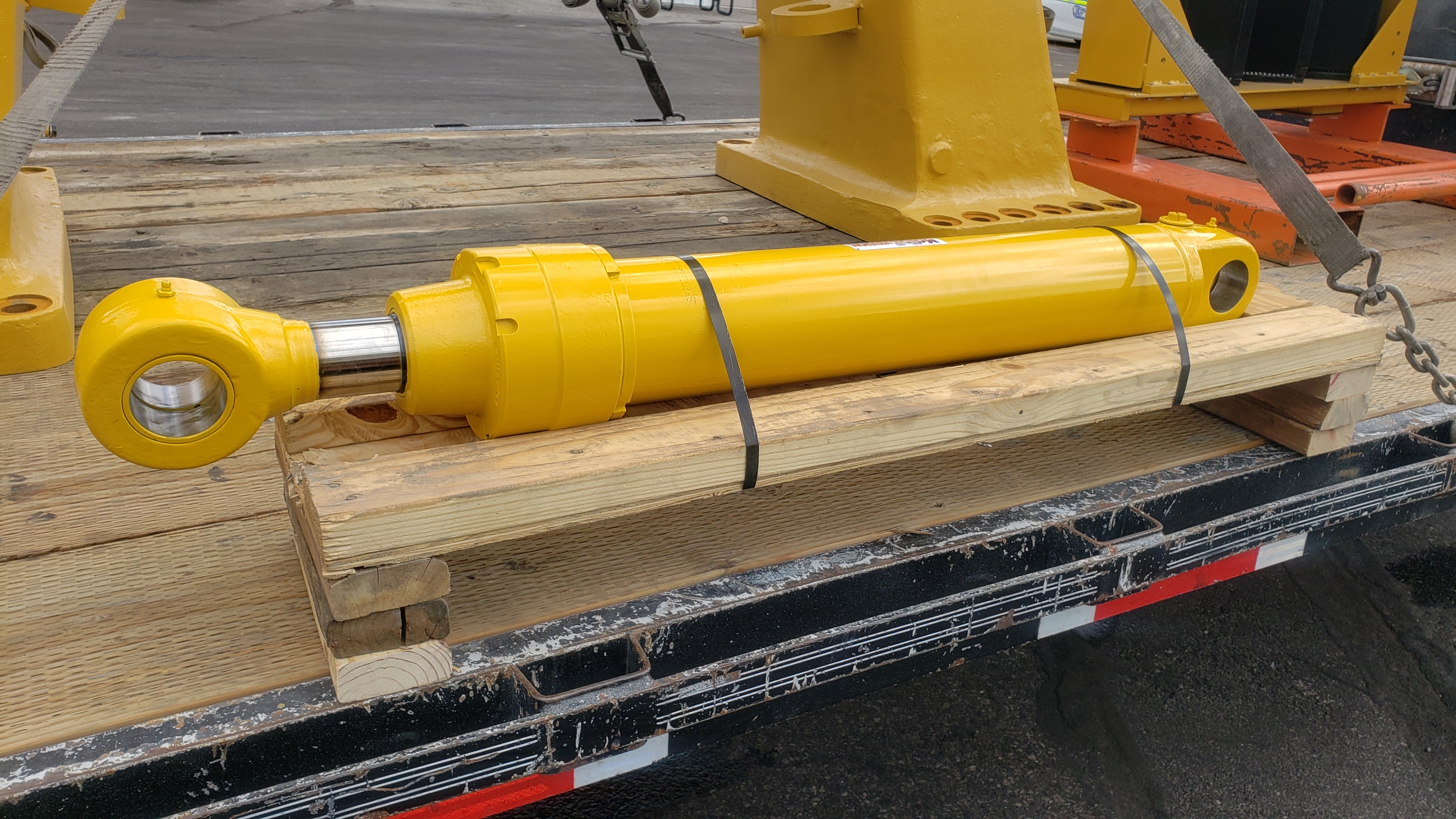

If you're experiencing any of the signs of hydraulic cylinder failure on your construction equipment, don't wait until it's too late. Conequip Parts offers a wide selection of new OEM, rebuilt, and aftermarket hydraulic cylinders for virtually every make and model of excavators, bulldozers, wheel loaders, and more. Click below to get a quote today!