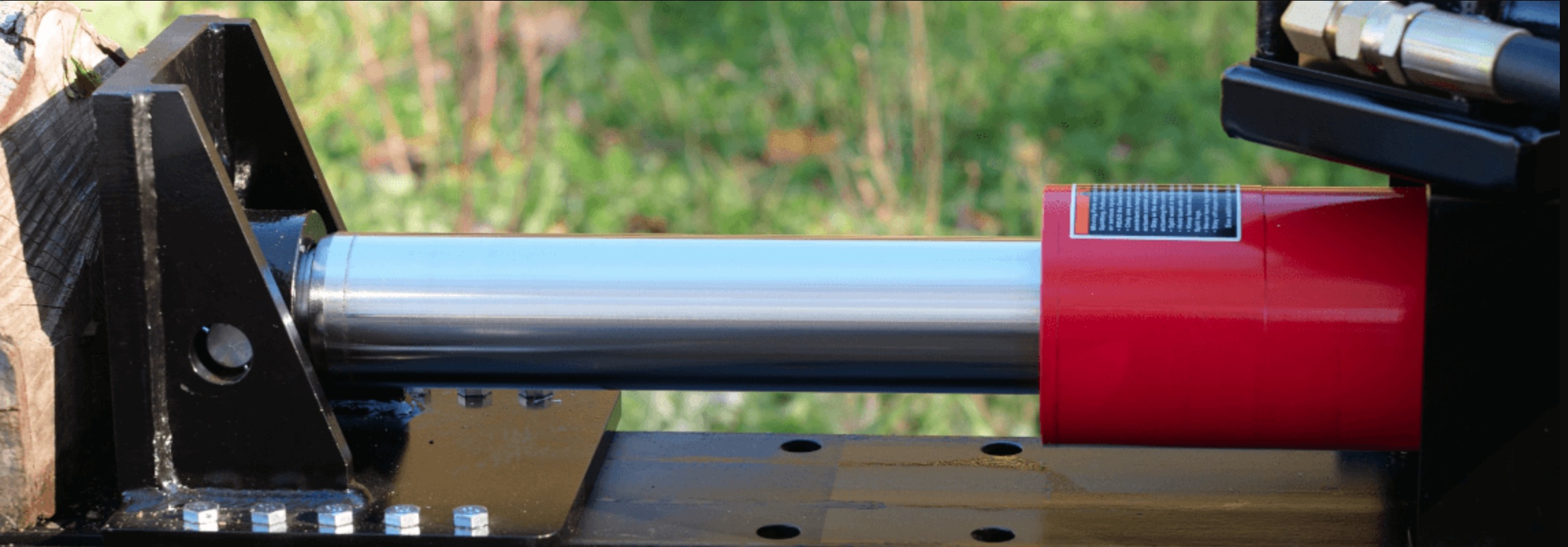

Excavator hydraulic cylinders are vital for the operation of heavy machinery, powering the arm, bucket, and attachments. Over time, these cylinders can wear out and require maintenance or a full rebuild. Here are the logical steps to rebuild an excavator hydraulic cylinder:

Step 1: Disassembly

- Remove hydraulic hoses, connectors, end caps, retaining rings, and other components holding the cylinder together.

- Note the order of parts for correct reassembly.

Step 2: Inspection

- Thoroughly inspect all components for wear, damage, cracks, leaks, or worn seals.

- Replace any damaged or worn parts.

Step 3: Cleaning

- Clean all components using a solvent and lint-free cloth.

- Remove debris and any remaining hydraulic fluid.

Step 4: Reassembly

- Begin reassembling the cylinder, installing new seals and other necessary components such as the piston or rod.

- Follow manufacturer's instructions for torque settings and specifications.

Step 5: Testing

- Test the reassembled cylinder for proper operation.

- Attach it to the excavator and perform tests to check for leaks or other issues.

If you're in need of aftermarket hydraulic cylinders for your excavator, Conequip Parts is your solution. We offer a wide selection of high-quality replacement cylinders to keep your machinery running smoothly. Click below to get a quote today!