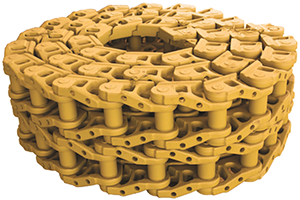

SALT vs. Grease Chains - Undercarriage

Your track machine has one of two types of chains. The difference is important to know as having one style over the other can cost you money either in the short or long term depending on what your machine is used for.

Most bulldozer and excavator owners have SALT (sealed and lubricated track) chains on their machine. Some machines have what are referred to as dry chains. SALT chains use pins with an internal reservoir of oil that flows through a radial hole in the pin and into the annular space between the pin and bushing. Seals in the link retain the oil. As long as seals remain effective, the oil reduces wear between the pin and bushing as the pin rotates within the bushing during operation.

Dry or “greased” chains are assembled with heavy grease between the pin and bushing. The greased-track’s seals usually aren’t as effective as those in SALT chains and eventually leak, allowing wear between the pin and bushing. Greased chains start seeing wear after about 2,500 hours.

Dry chains cost about 15% less than SALT chains. For this reason many machine owners trying to save on costs will go with dry chains. Of course, in the long run the accelerated wear on those chains will end up costing machine owners more in the long term.

Most aftermarket companies offer both dry and SALT chains. Savings to the customer can be as much as 50% of what dealers such as CAT, John Deere, Komatsu, Kobelco, Volvo and others charge.

The quality is comparable to the dealer’s product so the investment in aftermarket chains is a good one.

Have a Question About Undercarriage or Chains?