Final Drive Gear Oil Guide

The sales team at ConEquip Parts receives many calls each year from customers wanting to know what type of gear oil to use for their machine’s final drives.

If you don’t have access to the information from an owner’s manual or your local dealer, this article will help you select the proper industrial lubricant needed to keep your machine’s final drives running strong.

There are many factors to consider, and the assessment is rather involved but at the end of this article, you should be able to determine which grade gear oil your machine’s final drive needs.

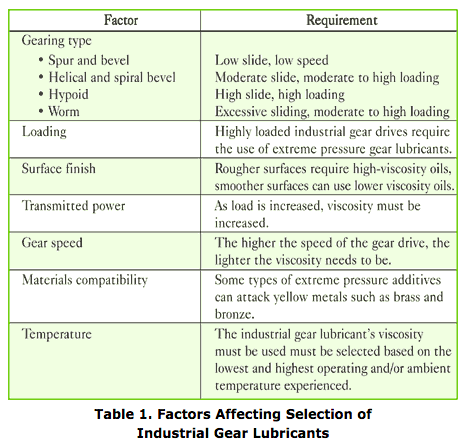

First, there is a table from Machinery Lubrication Magazine breaking down factors to consider along with the requirement.

Before you go to crazy trying to figure out which gear oil your final drive needs, you should first check the gear drive’s nameplate and see if the lubrication specifications are noted there.

Viscosity is the most important property of any lubricating oil. It provides the proper thickness of the oil at operating temperature. This allows the oil to help prevent direct rubbing between metal surfaces, pulling heat away from high impact areas, and moving debris away from the sensitive parts of the gear unit.

The higher the viscosity, the higher the load-carrying contribution to the industrial gear lubricant. The use of oil that’s too heavy can result in excessive heat, too much power losses, decreased gearbox efficiency, and improper oil flow.

One way to to determine what gear oil you need is by referencing the two tables below again provided by Machinery Lubrication Magazine. They show viscosity grade selection based on the industrial gear drive’s horsepower rating, reduction ratio, the speed of the gear drive in RPM and the type of lubrication method used to lubricate the gears.

There are other factors to consider. The type of gearing, the loads, and the transmitted power applied to the industrial gear drive, the speed of the gears, the operating and/or ambient temperatures, the materials used and the condition of the gears. All these factors can help with determining the type of industrial gear lubricant to use for a particular application.

Adding to the confusing, there are four different types of industrial gear lubricants you can choose from depending what type of final drive you have and what it is used for. They are Rust and Oxidation Inhibited Gear Oils or R&O, extreme pressure gear oils or EP, compounded gear oils, and synthetic gear oils.

You can learn more about those oils at Machinery Lubrication Magazine.

More than one type of enclosed industrial gear lubricant can be used in the lubrication of enclosed gear drives but it is important to use careful analysis of all factors outlined in Table 1. The final table below is a guide for selecting an enclosed gear lubricant for various gear types.

Finally, if you’re simply looking for a one gear oil fits all, you can go with SAE 85W-140. This is the weight oil used by replacement drive Terrapart in the UK according to sales manager Richard Huskinson.

“We always go by Hyundai’s recommendation as fundamentally all drives do the same work,” Huskinson said.

If you need have a final drive repair job and need parts, or need a complete final drive, call ConEquip Parts & Equipment today. A significant portion of our business comes from sales of finals and drive motors. We have access to all parts books and can easily identify the parts that you need for your machine.